Description

Use:

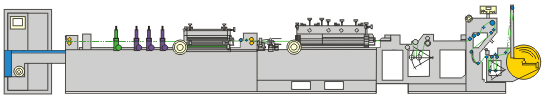

The machine structure is reasonable, easy to operate, high degree of automation, suitable for the production of plastic – plastic, paper – plastic has been composite materials, is the production of sealed, side seal and four sides of the ideal bag making bag equipment.

The main technical parameters:

| Maximum diameter of the web | ф800mm | ||

| Bag type | In the side of the bag side of the sealed bag | ||

| Maximum width of the web | 1100mm | ||

| Bagging speed | 150 pieces / min (pieces / mm ) | ||

| Mechanical design speed | Approximately 35 meters per minute | ||

| Bag width | 600mm | ||

| Bag length | 50-2400mm | ||

| Total power | 30Kw | ||

| Total Weight | 5000kg | ||

| Dimensions | L12550×W1700×H1830mm |

Note: due to bag type, material and other reasons the actual operating speed will decline.

Performance and features:

1. The machine adopts imported PLC, man-machine interface centralized control. Stable performance, easy to operate, maintenance. Operation interface, English can switch to each other.

2. Automatic discharge constant tension control, LPC automatic correction, AC constant speed automatic feeding

3. Imported dual servo drag material control

4. Upper and lower sealed AC variable frequency motor drive

5. Hot knife temperature using PID adjustment, non-contact automatic control, man-machine interface set.

6. Pneumatic multi-function automatic punching, side material removal automatic collection, with static elimination device.

7. Temperature: 0 ~ 300 ℃ adjustable.

8. Count: number, batch number automatically accumulated, with preset function.

9. Work: fixed length bag, photoelectric tracking bag

10. Punching method: can be set to continuous, interval, stop, stamping time can be preset

11. times the way: one to six times to send. The

12. Batch function: Workbench with batch function, batch number can be preset.